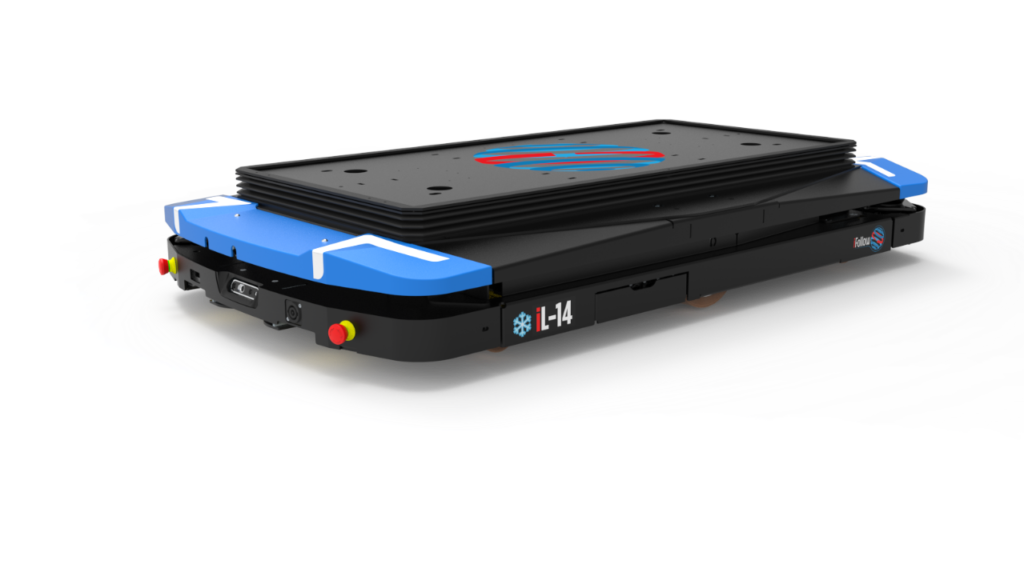

iFollow AMR for cold chain logistics

What is cold chain logistics?

Cold chain logistics is the technology and process that allows the safe transport of temperature-sensitive goods and products along the supply chain.

The cold storage industry has been facing some major challenges, such as:

Labor shortages rising wages for employees

Agility and productivity demands to satisfy the global market and customer needs

Energy efficiency

Space shortages

For example, Logistics UK in October claimed that “13% of traders are reporting severe warehouse staff shortages”; in November, the Cold Chain Federation noted “10% to 20 percent shortage rates” among its members.

How to keep up with high-efficiency demands when labor shortage is a serious issue?

And it will remain challenging as no secret

that working conditions in cold storage are not easy.

Automation with AMRs as an ultimate solution to cold chain logistics.

Technological advances such as automated transport in cold storage can help achieve these objectives and keep energy costs down. Also, as distribution centers continue to grow vertically, automation is not a question of luxury but an ultimate need.

Autonomous mobile robots have become increasingly commonplace in all types of industrial facilities in the past decades. They are used for inbound and outbound logistics as well as picking operations.

The flexibility of maneuvering around people and obstacles without any guidance, safety, and non-stop performance are just a few factors why plant managers choose this technology. However, not all AMRs can work in cold storage.

The technology needs to be robust and sophisticated enough to bear intense temperatures and transit smoothly from cold to ambient environments.

Which AMR to turn to when it comes to cold chain automation?

iFollow AMR robot for cold storage: How it works

iFollow came up with a revolutionary solution. We launched a range of robots for cold chain logistics that transport from 300kg to 1000kg payload down to -25°C.

The temperatures of the key electronic components are regulated by a servo system completely developed by our teams. Therefore, we ensure the absence of condensation, even when moving from a cold environment to an ambient temperature.

Our robots for cold storage have been implemented to improve safety and efficiency throughout cold storage facilities to effectively and safely reach products at various levels without putting the human workforce in dangerous situations.

Why choose iFollow’s autonomous mobile robots?

The cold chain industry has its specifics that are different from regular warehouses. We know the industry and developed a solution that meets the requirements.

ergonomics

Since space shortage is very present in cold chain logistics, iFollow robots can fit perfectly.

Our robots are the most compact in the market - 17cm high, able to transport up to 1000 kg.

productivity

The robot can transport two roll cages at once, which is one more of our competitive advantage.

Nonstop performances

Battery duration guarantees three-shift performance with less than 2 hours for battery charge.

Better traceability

Better traceability and accuracy of warehouse operations will lead to operational excellence.

Automation

The robot is capable of working in cold storage down to -25°C and is capable of smoothly moving to positive temperatures without any condensation.

Safety

Robots are safe as they maneuver around people and obstacles

user-friendly software

Mycelium, our fleet manager, is an intuitive software that allows real-time management and localization of robot flow, at the same time, preventive maintenance and troubleshooting.

It is available in multiple languages, such as English, French, and Japanese.

layout freedom

With AMRs, you have the flexibility of layout freedom - no need to change the existing infrastructure to implement robots in your cold chain storage.

AMR standard

We have 4 iLogistics robots: iL300, iL600, iL1000 and iL1200 that carry various payloads ranging from 300 kg to 1.2 tons (660 lbs to 2,650 lbs).

The AMR iFollow robots are perfectly suited to the needs of logistics and industry.

How to get started with AMR implementation in cold storage?

Our expert team for automation in cold chain logistics will help you reach your objectives. We have the right technology and expertise to guide you from A to Z in your automation project.